The Occupational Safety and Health Administration (OSHA), as part of its work to prevent construction site accidents, developed a program that it calls “Construction Focus Four Training.” This program is meant to teach site supervisors, superintendents, foremen and workers how to recognize and mitigate the four leading construction site hazards, which are sometime called the “Fatal Four.”

The Focus Four are:

- Falls

- Struck By Object

- Electrocution

- Caught-In / -Between.

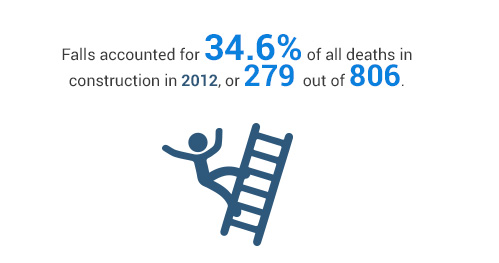

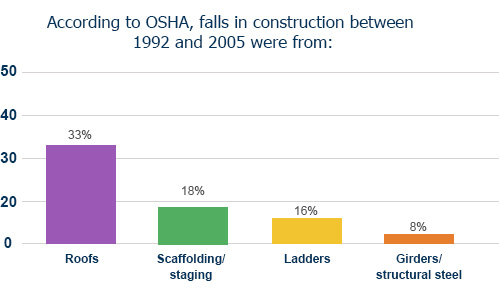

Fall Hazards

A fall hazard is anything at a work site that could cause a worker to lose his or her balance or bodily support and fall. Any walking or working surface can present a potential fall hazard.

Working at a height of four feet or more puts a worker at risk, OSHA says. OSHA requires protective gear for:

- Construction workers working at a height of six feet or more

- Scaffolds at 10 feet or higher

- Steel workers on walking / working surfaces with unprotected sides or edges above 15 feet. (There are different rules for controlled decking zones between 15 and 30 feet.)

- Work at any height over dangerous equipment and machinery.

About 25% of fatal falls included falls through existing floor openings, from nonmoving vehicles, from aerial lifts and falls due to other reasons.

Workers can protect themselves from fall hazards by using ladders and erecting scaffolding safely and by using fall protection equipment, including:

- Guardrail systems on the level of a hazardous work surface

- Safety net systems no more than 30 feet below a hazardous work surface

- Personal fall arrest systems.

A personal fall arrest system consists of an anchorage, connectors and a full-body harness that work together to break a worker’s fall.

Struck-By Hazards

When the impact between a worker’s body and an object or piece of equipment causes the worker’s injury, this is known as a struck-by accident. It is distinguished from caught-in or -between injuries by the fact that the impact alone causes the harm as opposed to an injury from being crushed.

Struck-by injuries are typically caused by:

- Flying objects, including objects thrown by people or machinery like from a nail gun

- Falling objects from an elevation to a lower level that leave a worker crushed, pinned or caught under them (not including collapsing materials or structures)

- Swinging objects, such as a load being lifted by man or machine, or materials in transport that may swing, twist or turn

- Rolling objects, including motor vehicles or sliding objects or equipment.

Crane-related accidents are typically struck-by accidents such as injuries caused by workers being hit by a crane load as it swings from one location to another or by a falling load that was improperly rigged. Deaths from crane collapses and from electrocution when cranes strike power lines are also considered struck-by accidents, OSHA says.

Crane-related accidents are typically struck-by accidents such as injuries caused by workers being hit by a crane load as it swings from one location to another or by a falling load that was improperly rigged. Deaths from crane collapses and from electrocution when cranes strike power lines are also considered struck-by accidents, OSHA says.

There are numerous OSHA standards for setup and operation of cranes and other heavy equipment such as excavators, backhoes and bulldozers. Construction site supervisors should be sure that workers assigned to operate this equipment are trained and capable and that others understand that an unqualified worker cannot “fill in” for even the simplest task.

Power tools must operate properly and have all proper safeguards in place to ensure they do not eject pieces or materials beyond what is normal and expected. Workers should not be required to use tools with loose, cracked or splintered handles, or mushroomed heads. They should have equipment to protect feet, eyes, ears and hands, and wear hearing protection.

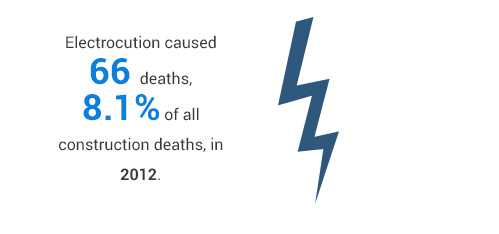

Electrocution

Electrocution occurs when a person is exposed to a lethal amount of electrical energy. Electrical shock is a reflexive response to the passage of electric current through the body.

A burn is the most common electrical shock-related injury. Electrical burns result from heat generated by the flow of electric current through the body. Arc/flash burns are high temperature burns caused by an electric arc or explosion. If electricity ignites an explosive mixture of material in the air, an explosion can occur.

Fires typically result from problems with “fixed wiring” such as faulty electrical outlets and old wiring. Problems with cords (extension and appliance cords), plugs, receptacles and switches also cause electrical fires.

Contact with overhead power lines, contact with energized sources (live parts, damaged or bare wires, defective equipment or tools) and improper use of extension cords and other and flexible cords cause the most electrocution deaths, OSHA reports. The agency points out that the covering on an overhead power line is primarily for weather protection. If a worker touches a power line, covered or bare, death is likely.

Many electrical accidents are caused by the poor condition of equipment such as a missing safety shields, a missing ground pin on an extension cord or poorly made splices in cords.

In other addition to inspecting electrical tools and extension cords to ensure safety features are intact, workers should follow log-out/tag-out procedures for electrical equipment and machinery. They should also maintain a safe distance from overhead power lines and use ground-fault circuit interrupters (GFCI) in electrical installations.

Caught-In / -Between Hazards

A construction site injury considered a “caught” accident is one in which an injury occurs as a result of being crushed between objects, as opposed to when the impact of an accident alone causes an injury. This includes injuries resulting from a person being squeezed, caught, crushed, pinched or compressed between two or more objects or between parts of an object. Examples are:

- Cave-ins (trenching)

- Being pulled into or caught in machinery and equipment

- Being compressed or crushed between rolling, sliding or shifting objects, such as semi-trailers and a dock wall, or between a truck frame and a hydraulic bed being lowered.

The type of hazards that lead to “caught” accidents sound familiar to any construction worker:

- Machinery that has unguarded moving parts or that is not properly locked-out during maintenance

- Heavy equipment that could tip over

- Unprotected excavations and trenches

- Walls that could collapse during demolition

- Work conducted between materials that are being moved and immovable structures, vehicles, or equipment.

Moving or unguarded machinery can catch body parts and injure a worker, or trap clothing and pull a worker into the machinery. Tipping machinery or collapsing walls, structures or trenches can crush workers caught underneath. If a pile of material being moved by a crane or a forklift gets loose, anyone caught between it and where it lands is sure to be injured.

For each of these potential hazards, there are safety standards that should be taught as part of worker training, particularly for supporting trenches, following lock-out/tag-out rules and rigging cranes.

Even a veteran construction hand can benefit from a reminder to be aware of the equipment around him or her and to never put themselves between moving materials and an immovable object.

Employers have a duty to ensure that equipment and machinery used on a construction site has proper guards, that heavy machinery is set up correctly and that materials are stacked and stored so accidents from tipping or collapse do not occur.

OSHA’s Educational Material

OSHA has its full Focus Four educational curriculum available online, including instruction guides for each hazard topic, PowerPoint presentations and handouts. These materials illustrate many of the safety recommendations in the educational material. It is all free and easily downloadable.

If you are a construction site manager, you might consider how to use this educational material to keep your workers safe. If you are a construction worker, you can examine the material for your own education or suggest its use to your supervisors.

See Also: